Bearing Isolators are Dynamic Particle Filters

Bearing protection devices (BPDs) have many names including “seal”, “isolator” and “labyrinth”. One name which is not commonly used but most accurately describes them all is “filter”. What’s the goal of a filter? To minimize the passage of particles from one space into another control volume. You can think of the air filter in your home. It’s designed to prevent airborne particles from flowing into your HVAC system. Similarly, BPDs are designed to prevent outside particles, or contaminants, from flowing into the bearing housing. A reliable device also prevents the internal liquid particles (lubrication) from flowing out, making it a bi-directional particle filter. Another unique thing about BPD filters is they must filter particles between a static surface and a rotating surface. Therefore, they are known as “dynamic filters''.

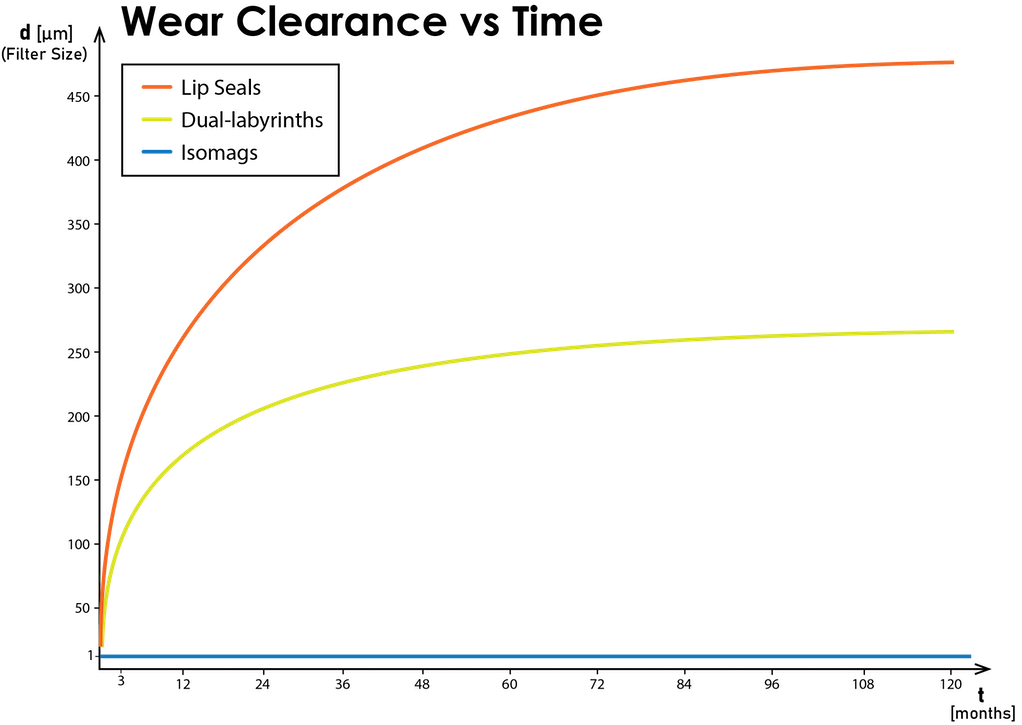

Anyone who knows about rotating equipment reliability can tell you how even a small number of contaminants can be fatal to bearings. In fact, the ISO 281 standards have taken contaminants into account in what they call the modified bearing life calculation (L10m). A much more accurate method than the traditional L10 calculation. So how do they account for something as abstract contamination? By the “filtered particle size” constant, or the smallest particle size that is allowed passage into the bearing housing. Surprisingly, per the ISO calculation, just a 30% increase in filtered particle size results in a 50% decrease in bearing life!

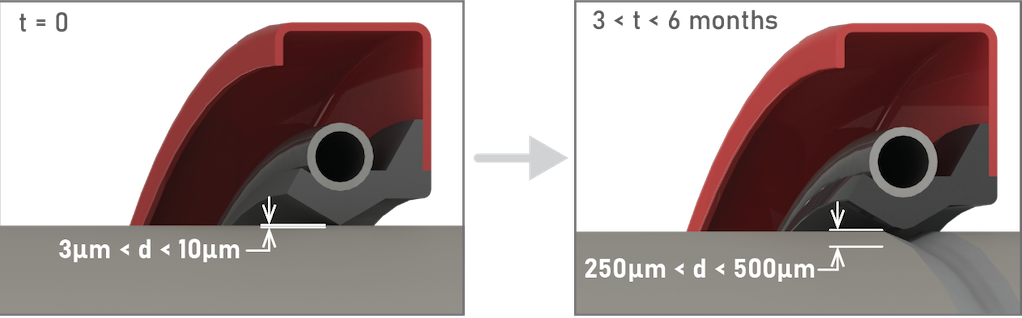

While all bearing protection devices can be considered dynamic filters, they are not all created equal. In fact, in most BPDs the filtered particle size grows rapidly over time. Take lip seals for example, due to the quick wear life the filtered particle size can increase by over 50x in just 3 months as shown in the figure below.

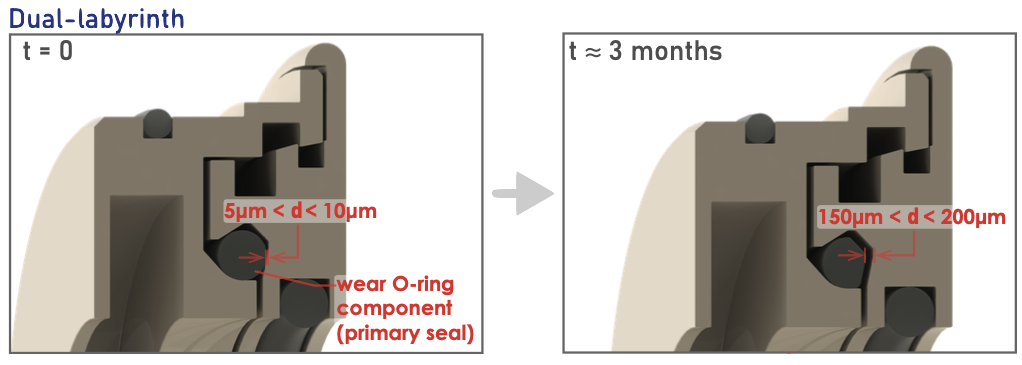

Similar to lip seals, dual-labyrinths have a wearing component between the stationary and rotating components. This wearing component is commonly some sort of O-ring or even a miniature lip seal. Also, like lip seals, this causes the filtered particle size to quickly grow over time due to wear, approximately 20x in 3-6 months.

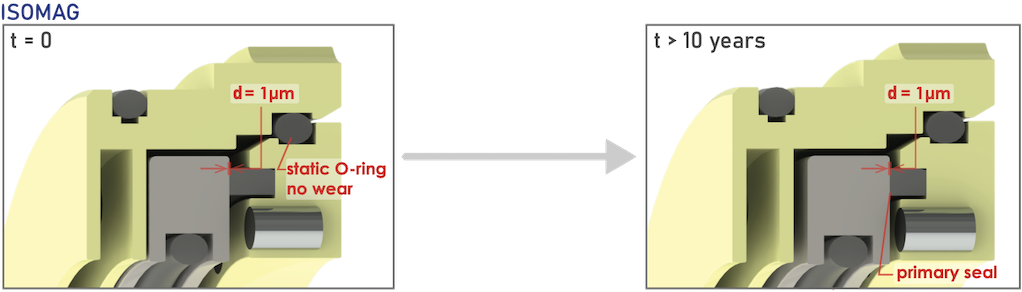

Now, what happens if you have magnetic energy constantly pulling two sealing faces together? You get a filtered particle size that is consistent for the entire life of the seal instead of one that grows over time as with other BPDs. This is the most advantageous feature of ISOMAG magnetic-face bearing isolators. Not only does the filtered particle size not grow over time, but it is also extremely small, 1-2 microns . 1/10th the size of a water particle. It will remain this small after 10 years of operation.

Finally, if we plot the filtered particle size over time you can see the difference between the three types of BPDs mentioned.

Now you know, when you are purchasing a “bearing isolator” what you are really buying is a dynamic particle filter. It's important you buy one that does not decrease in quality under operation as the majority of BPD offerings do. ISOMAG is the only bearing protection device available that can guarantee its filtered particle size will remain <2 after 75,000 hours of continuous run time.

A brochure for ISOMAG magnetic bearing seals can be found here. Also, as a reminder, Isomag bearing isolators can be custom made to fit your machine. Contact our customer service team and we will help you find the ideal solution for your needs.