True innovation with

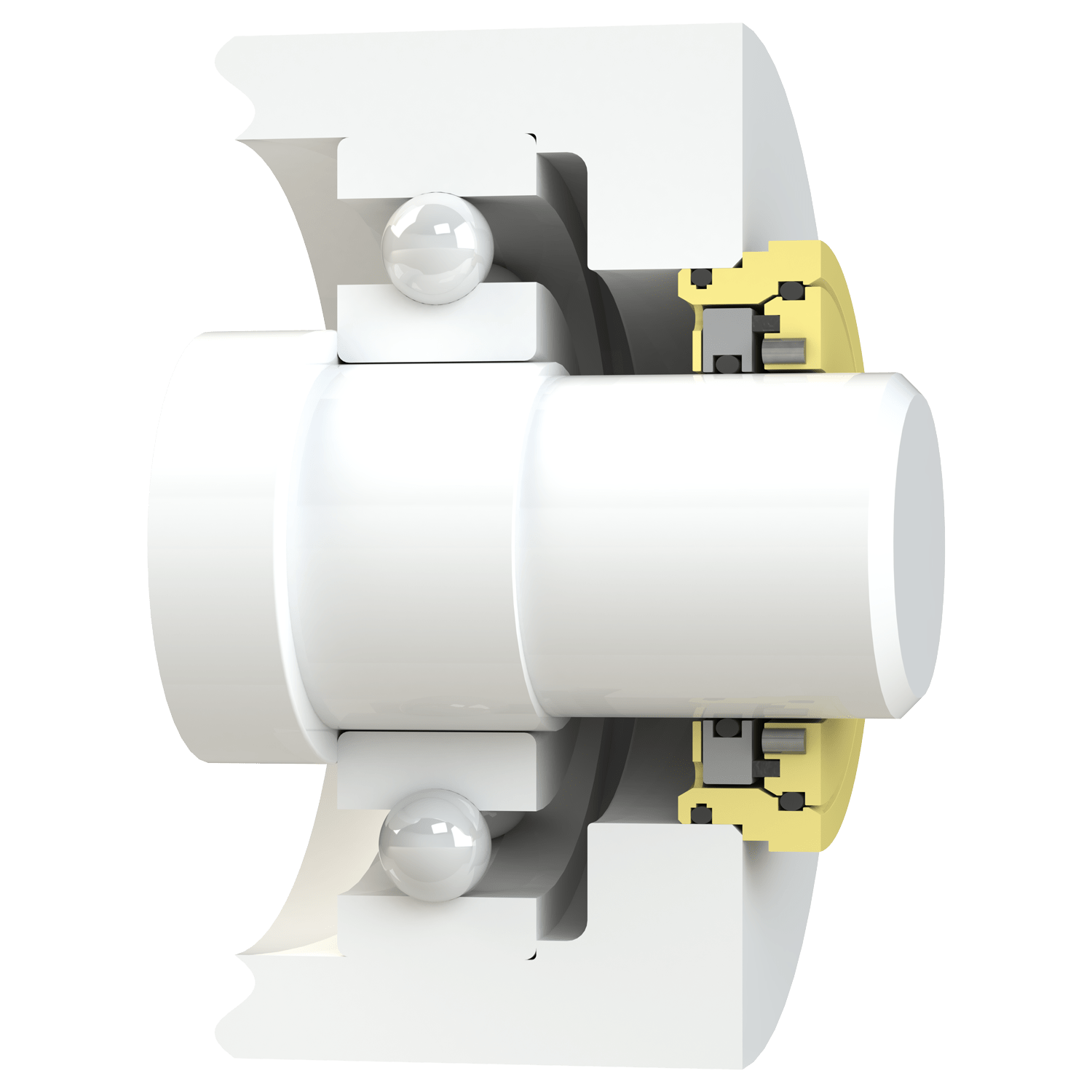

Magnetic-Face Bearing Isolators.

ISOMAG magnetic-face bearing seals save you money and extend bearing life up to 75,000 hours.

“We are very pleased with Isomag’s ability to stop contamination at such high shaft speeds during both dynamic and static conditions.”

"I’m very impressed with the longevity of the Isomag magnetic seal technology, even at high speeds in a salty and humid environment.”

"The end user is very satisfied with Isomags performance.The seals installed in 2008 are still running leak free today.”

"I believe we have greatly improved the reliability of this gearbox by upgrading these shaft seals.”

A smarter seal for the long haul

ISOMAG is the original long-term, liquid-tight magnetic-face bearing seal. Our advanced non-contacting seals outperform other isolators to protect your rotating equipment by extending bearing life, eliminating wear, decreasing maintenance and rebuilds, and preventing lubricant leakage.

Overcome key rotating equipment challenges.

Wear and Tear

Preserve shaft integrity and maximize bearing life.

Contaminants

Keep oil and grease exactly where it’s supposed to be.

Maintenance

Guard equipment bearing housing with a liquid-tight seal.

Downtime

Reduce costly time needed for maintenance and rebuilds.

Trusted the world over

ISOMAG’s superior face-seal technology protects the bearings on thousands of rotating equipment applications including: