The Best Bearing Seal For Philadelphia Gearboxes is Isomag Bearing Seals

Philadelphia Gear gearboxes are an industrial workhorse, found on oil refineries, drilling platforms, chemical plants and paper mills. Most companies run them to failure, which often times is an impressive 10+ year run before a repair is needed. Their one weakness is the lip seals that are installed. Oil seal are able to contain forced lubrication systems or oil bath lubrication environments. They do however wear out in about 6-8 months on continuous use. On top of that, the lip seal wears a grove into the shaft, making it necessary to either refurbish the shaft or get a new one when it's time to repair. Regular labyrinth isolators don't scar the shaft but perform poorly in forced lube systems or flooded environments.

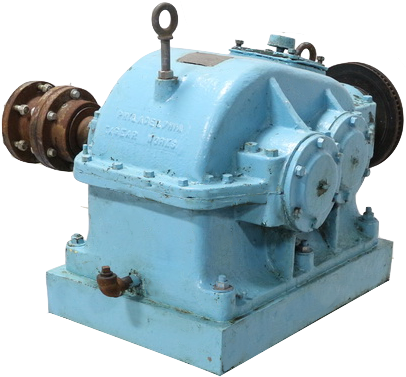

Invista in Victoria, Texas needed Isomag bearing isolators to seal their Philadelphia Gear 3509 gearbox. Isomag bearing seals are the best of both worlds. Isomag bearing isolators are a positive seal that wont damage the shafts of your gearbox, and work in horizontal or vertical up or down positions for the right angle gearboxes such as this gearbox with a horizontal high speed shaft and a horizontal low speed shaft. Isomag bearing isolators also work perfectly in grease lubrication environments.

A brochure for Isomag bearing isolators for gearboxes can be found here. Also as a reminder, Isomag bearing isolators can be custom made to fit your machine. Contact our customer service team and we will help you find the ideal solution for your needs.

#PhiladelphiaGear #Invista #Chemical #chemicalplant #Gearbox