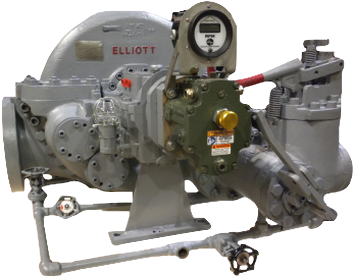

Keep Condensate Out Of An Elliott DYR Steam Turbine with Isomag Bearing Seals

Isomag magnetic bearing isolators stop water and condensate from contaminating your turbine oil. Isomag bearing seals utilize proven lapped flat face sealing technology putting an end to leaky labyrinths, and eliminating the need to drain water from your turbine oil.

The Elliott DYR family of steam turbines are a popular machine that readily accepts our bearing seal upgrade. The Isomag bearing isolators replace the OEM labyrinths with little or no modification required. Isomag magnetic bearing seals are mounted inside the bearing housing so as to place them away from the heat source and directly in the lubricating oil. We also recommend using a shaft mounted steam deflector with the inboard seals. This will further reduce the operating temperature at the seals and bearings.

Isomag bearing isolators are designed to last for years and never damage your turbine shaft. To insure a quality fit, Isomag bearing seals are best installed during a complete turbine overhaul.

A brochure for Isomag bearing isolators for steam turbines can be found here. Also as a reminder, Isomag bearing isolators can be custom made to fit your machine. Contact our customer service team and we will help you find the ideal solution for your needs.

#Elliot #SteamTurbine #OilGas #OilRefiniery #Chemical #chemicalplant #PaperMill #PulpPaper