Isomag Bearing Seals Solve Repulper Contamination Issues For Paper Industry

Welcome to the world of paper mill re-pulpers. Imagine the tub in a 30 foot diameter top loading washing machine. Inside the tub are several sets of rotating blades and paddles. Now fill it with 200 pound bundles of used recycled paper and water. The shaft that drives the blades and paddles enters the tub from the bottom and the shaft is rotated by a gearbox that is the size of an automobile. The rotating shaft is sealed to the tub with a stuffing box filled with rings of square cross section rope packing which is compressed by a follower gland (flange). The amount of packing compression is set by adjusting the tightness with hex nuts on studs. Mechanics are supposed to adjust the packing gland to reduce the leakage rate down to a fast drip or a very small stream. If the packing compression is too loose, it will leak too much, and if adjusted too tight, the packing and the shaft will quickly wear out or burn up.

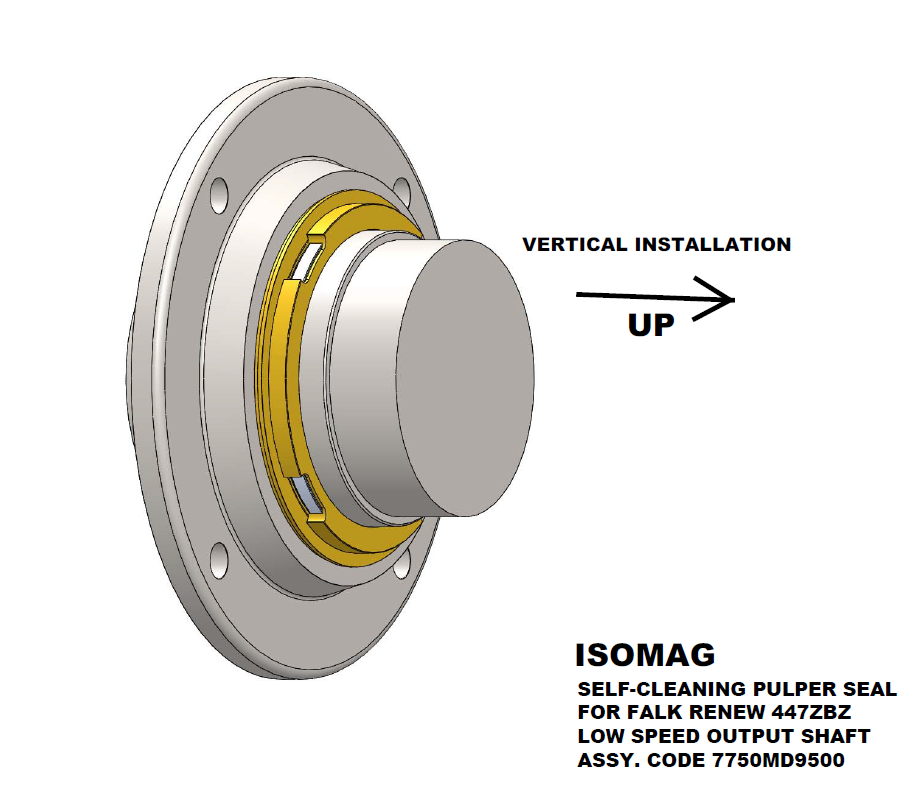

This is an ugly and messy application. Isomag magnetic bearing isolators' approach combines our flat face sealing technology with simple concepts of practical machine design to prevent the ingress of water into the gearbox.

If it were an easy application a lip seal might be good enough. Do not let the mess and filth scare you away. Isomag bearing isolators have what it takes to make a big difference.