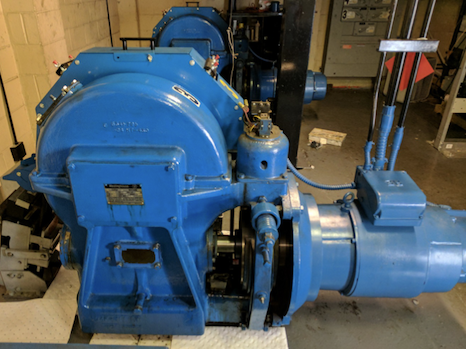

ISOMAG Bearing Seals Improve Reliability For Schindler / Westinghouse Elevator Gearboxes

Have you ever been stuck on an elevator? Or walked into a commercial building where the elevator was out of commission and had to take 20 flights of stairs? Neither of these scenarios are fun. Elevators are highly critical machines in commercial buildings and there are few things more troublesome for both the building owner and occupants than an elevator which is out of commission. So, why do these elevators stop working? The majority of the time this is due to the elevator gearbox.

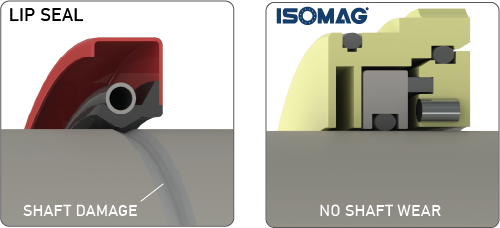

Elevator gearboxes, such as the Schindler / Westinghouse #38, are often installed by the manufacturer with conventional radial lip seals. These lip seals use the shaft as the primary sealing surface, quickly wearing out and scarring the shaft. This is especially the case on these worm drive gearboxes whose shaft thrusts axially causing extra rubbing under the lip of the seal, leading to a deeper and wider fret in the shaft. Lip seal failure and shaft wear of this magnitude can typically take place within 3,000 hours of runtime. On elevator gearboxes that is between 3-6 months. Once a clearance is worn, a gear lubrication leak is inevitable. This can lead to bearing failure due to lack of lubrication and a potential safety hazard for both the maintenance team and elevator passengers.

Schindler saw the need for a positive, long-term bearing seal for this application. ISOMAG was able to provide a solution that not only eliminated the oil leaks, but no longer caused shaft fretting to the expensive gearbox shafts. ISOMAG’s unique magnetic face technology allows a long-term sealing solution (>75,000 hours) while not using the host equipment as a wearing surface. The customer has been very pleased with ISOMAG’s performance since being installed in 2018. The gearboxes are still running leak free today.

A brochure for ISOMAG magnetic bearing seals can be found here. Also, as a reminder, Isomag bearing isolators can be custom made to fit your machine. Contact our customer service team and we will help you find the ideal solution for your needs.

#Elevator #Gearbox #Schindler #Westinghouse