Isomag bearing isolators solve oil leak issues in large electric motors.

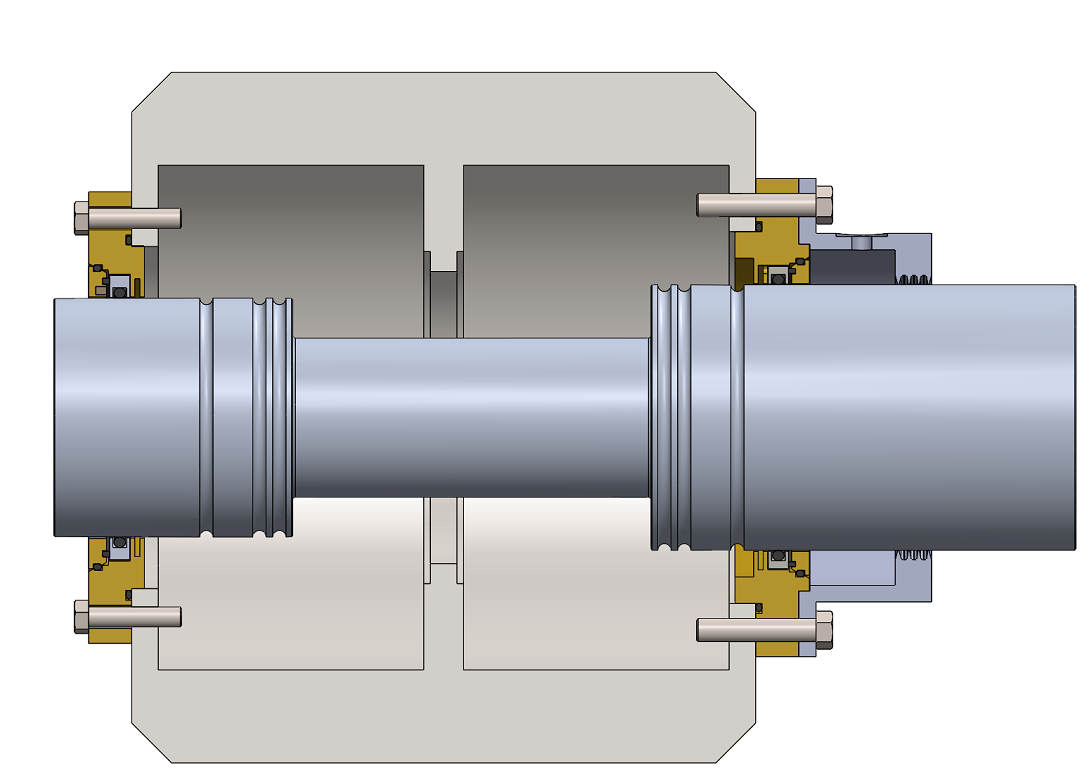

Large Siemens electric motors on energy pipelines were having issues with bearing oil leaking past the stationary labyrinths shown in Figure 1 below. As is common in large electric motors, the motor fan will force the bearing oil to migrate past the labyrinths. The oil combines with outside contaminants to create an oil sludge as seen in Figure 2. This sludge adheres to the windings inside the electric motor greatly reducing its efficiency and life cycle. Isomag bearing isolators provide a solution to this recurring issue by replacing the labyrinths with our magnetic face seals (see Figures 3-4). Isomag's positive, liquid-tight seal prevents the oil from migrating past its faces. Since installed in 2008, there have been no reports of oil leaks or sludge build up inside the electric motor stator.

Application Summary:

Problem solved: contamination

Electric Motor: Siemens

Model: WP II

Power: 3500 HP

Shaft Diameter 1: 4.500”

Shaft Diameter 2: 5.000”

Speed: Oil ring splash

Year installed: 2008

Previous bearing protection: Stationary Labyrinth

#CaseStudy #ElectricMotor #Pipeline #EnergyPipeline #Energy #OilGas