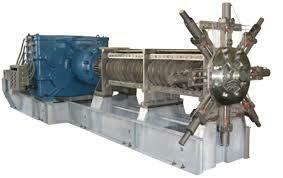

Isomag Bearing Isolators Prevent Ingress of Contaminants in Anderson Moisture Expeller

Lanxess Corporation in Orange, Texas was in need of a better bearing protector for they Anderson Moisture expeller. They were having problems with both ingress of water and contamination as well as the egress of lubrication getting past the lip seals used by the manufacturer. This moisture expeller is a vital component in their process, so this payload machine could not afford much down time.

Isomag was specified into this application by Lanxess to hold in the forced circulated lubrication, as well as keep the water out of the housing in 2015. What was once an issue that showed signed after 6-8 months, the Isomag bearing isolators have been leak free for 3 years and counting.

A brochure for Isomag bearing isolators for gearboxes can be found here. Also as a reminder, Isomag bearing isolators can be custom made to fit your machine. Contact our customer service team and we will help you find the ideal solution for your needs.

#Gearbox #Anderson #Lanxess #Chemical #chemicalplant #BearingIsolator #BearingProtector