Installation Of Isomag Bearing Isolators On Valmet Paper Roll Machines

Installing Isomag bearing isolators on a Valmet paper roll machine, a crucial component to the paper making process, can prove troublesome if proper precautions are not taken. In 2010 Intenational Paper in Selma, Alabama used the following Isomag bearing isolator installation procedure, and have had their machine running for 10+ years.

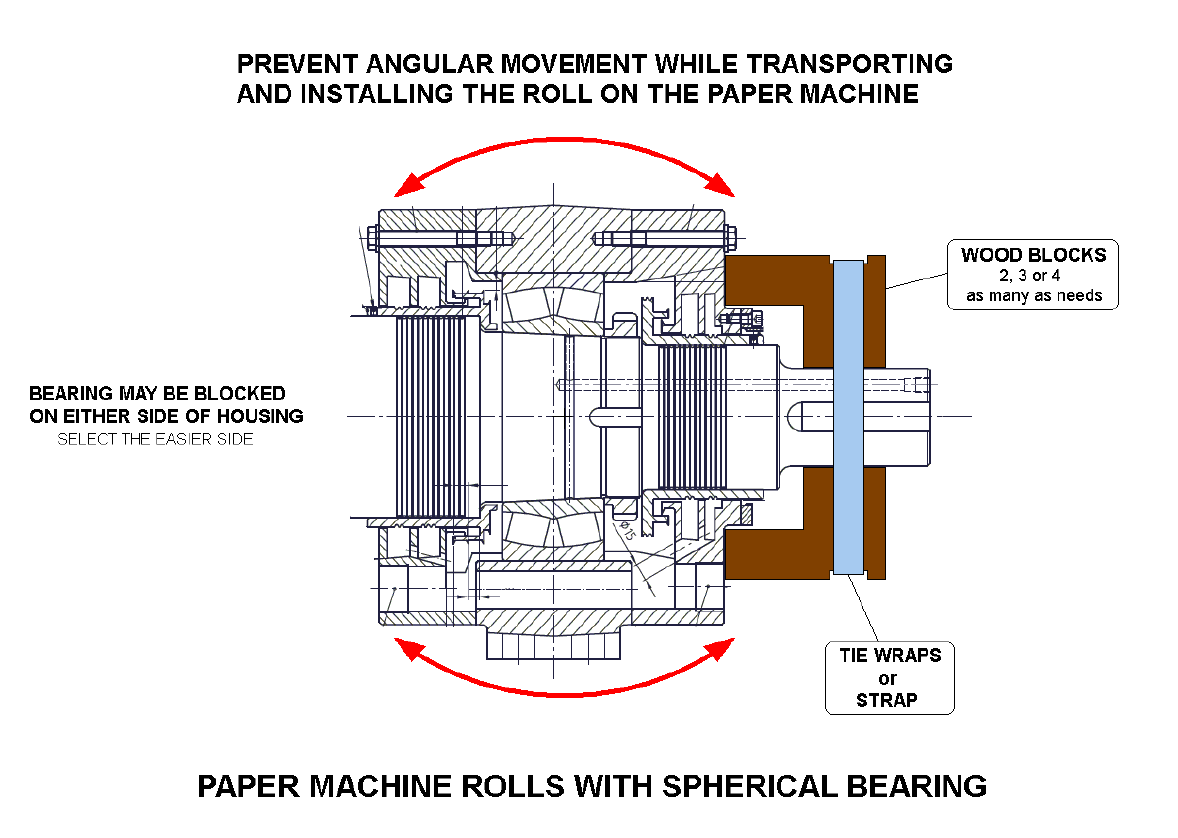

The key here is to prevent angular movement of the shaft in relation to the housing during the installation/transportation process. Typically the roll is assembled with the housing in shop and then transported to its operating position by use of a crane. During this transportation process, it is critical to stabilize the shaft, maintaining alignment with the housing bore. This can be done by attaching wooden blocks that keep the shaft in line with the housing as shown in Figure 1. While it’s a crude solution, it works. If the wooden blocks are configured correctly (as shown in the figure) they will ensure the shaft stays in line with the housing, and therefore preventing the impact on the bearing isolators.

#Valmet #PaperRoll #InternationalPaper #PaperMill #PulpPaper #BearingIsolator #BearingProtector