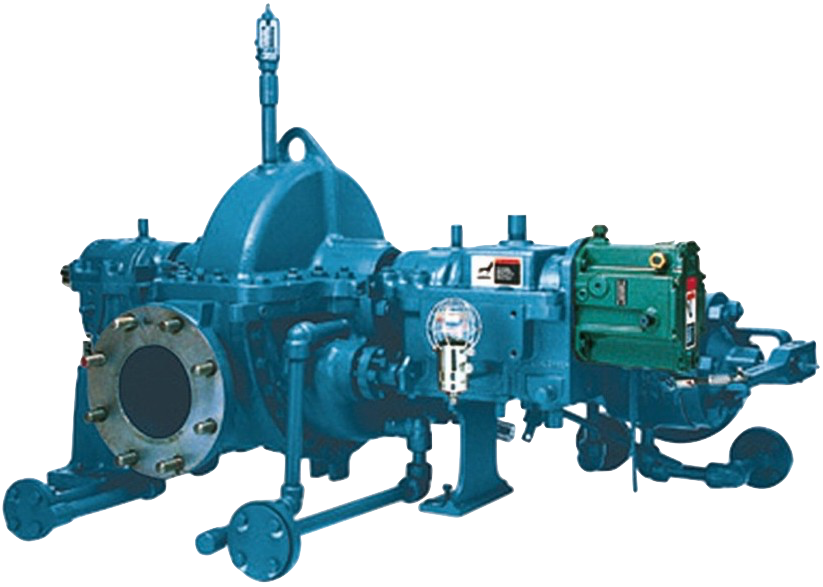

Dresser Rand SST 350 Steam Turbine Best With Isomag Bearing Seals

Water contamination in bearing oil is a common recurring issue for steam turbines in the oil and gas industry. Labyrinth isolators fail to stop condensate from entering the bearing housing as steam dissipates from the carbon box. PBF Energy in Toledo, Ohio has many of steam turbines in operation, and a common maintenance procedure is to drain the water out of the bearing housings.

After another failure on their Dresser Rand SST 350 steam turbine, a sales representative from John Crane introduced the refinery to Isomag magnetic bearing seals as the perfect solution to their steam ingress problem. PBF specified Isomag magnetic bearing isolators for this Dresser Rand SST Steam Turbine. It was a hot job, and needed a quick turnaround. Isomag was able to measure, engineer, and manufacture three custom fitted bearing seals for them in less than 48 hours.

PBF put an end to this issue by replacing the existing labyrinth isolators with Isomag bearing isolators. Since installed in 2008, the end user reports that the seals are running smoothly at low temperatures with no evidence of water contamination. The old practice of evaporating water out of the oil twice a year is no longer necessary.

A brochure for Isomag bearing seals for steam turbines can be found here. Also as a reminder, Isomag bearing isolators can be custom made to fit your machine. Contact our customer service team and we will help you find the ideal solution for your needs.

#DresserRand #SteamTurbine #PBFEnergy #JohnCrane #OilGas #OilRefiniery