Coal Fired Power Plants & Isomag Bearing Isolators

Isomag bearing isolators solve coal dust contamination for induce draft fan motors in coal fired power plants.

Problem: Coal fired power plants in Illinois were having bearing issues on large GE motors due to coal dust entering through the default labyrinth type isolator and contaminating the bearing lubrication.

Operating Specs:

Motor: GE 6,0000 HP

Shaft Diameter: 9 inch

Speed: 890 RPM

Lubrication: Forced circulation (1.5-2 GPM)

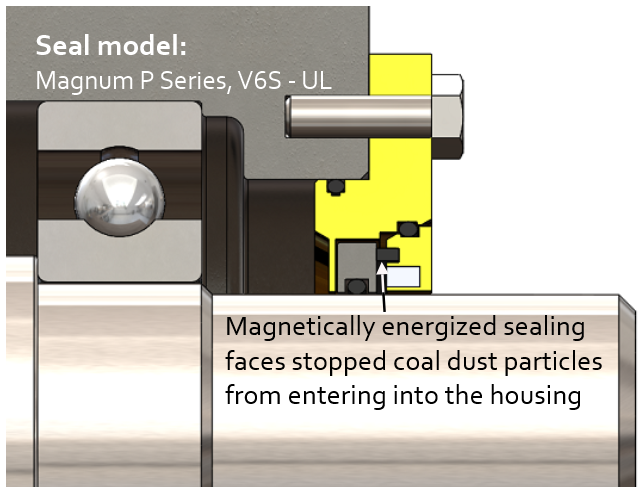

Solution: Replace the labyrinth type isolators with Isomag’s magnetic bearing isolators. Unlike labyrinths, Isomag's bearing isolators create a positive seal eliminating contamination ingress and oil leaks.

Figure 1: Isomag MP-V6S Bolted Flange Seal

Statement from motor rebuilder L&S electric: “The end user is very satisfied with IsoMags performance. The seals installed in 2008 are still running leak free today”